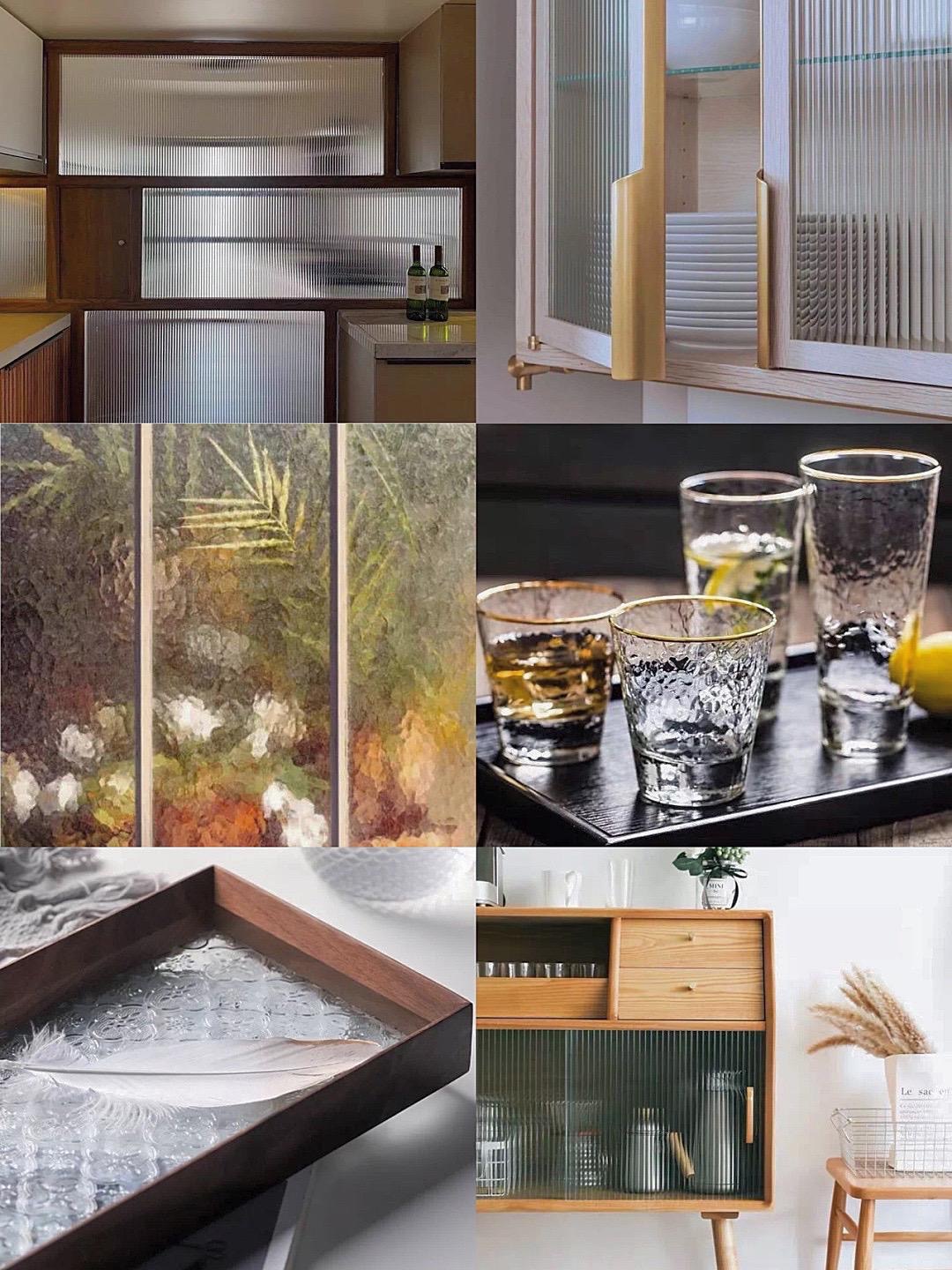

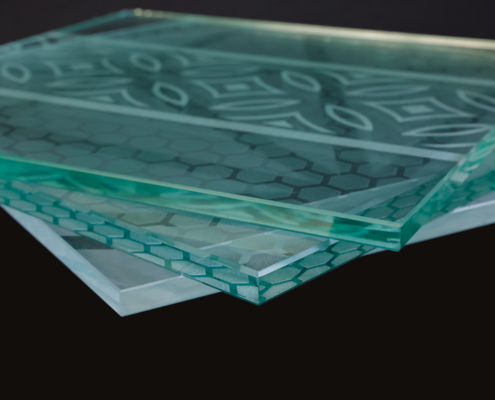

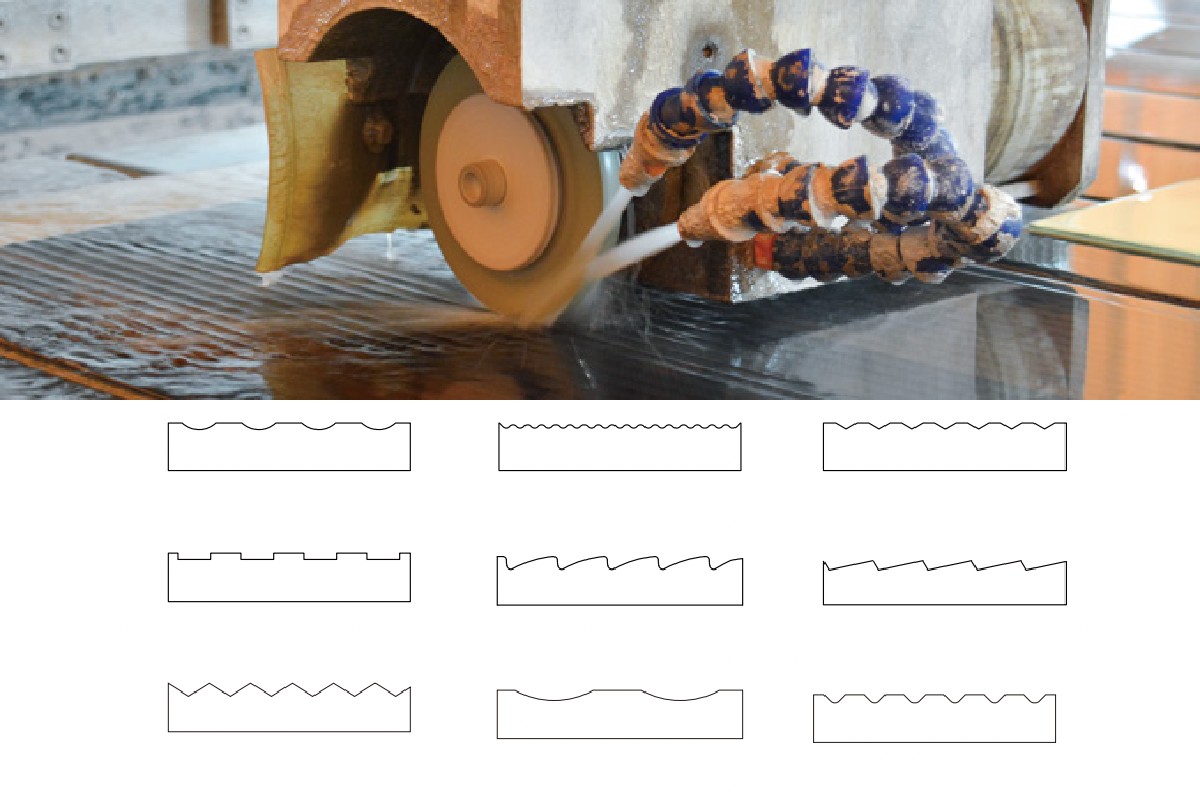

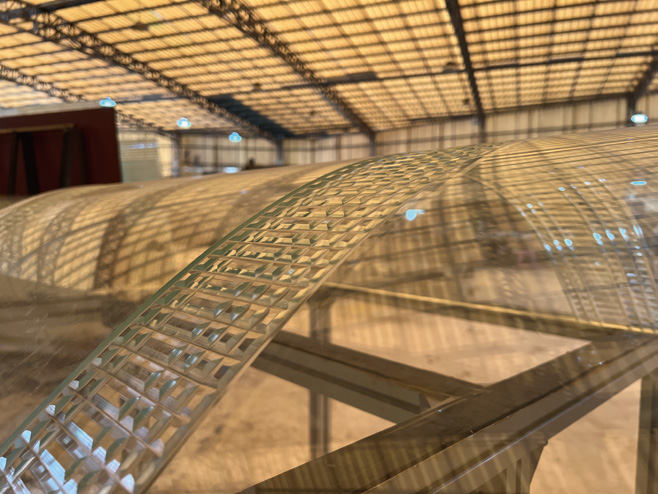

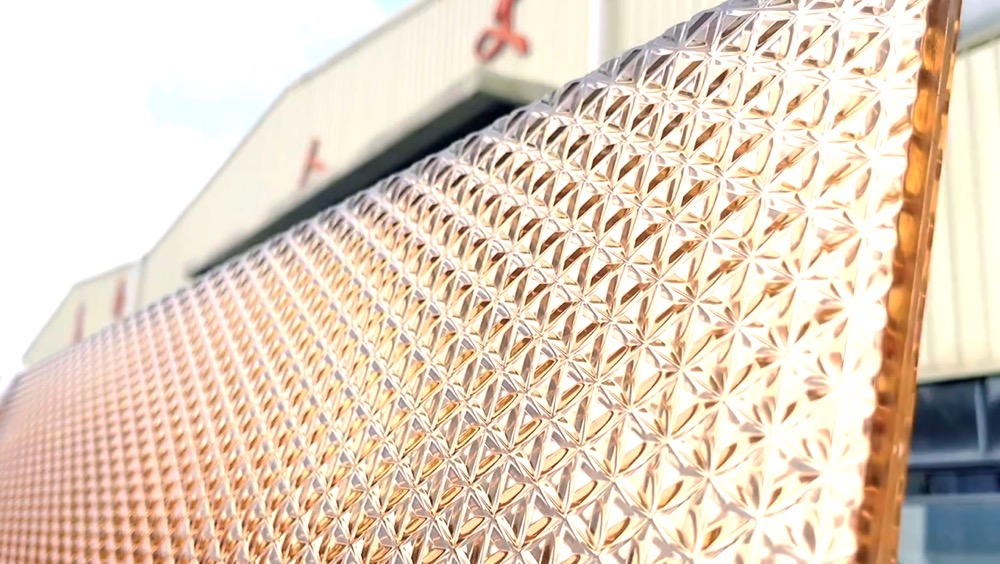

Textured glass is a decorative glass that features patterns or designs created on the glass surface through unique manufacturing processes. It finds applications in various settings, such as doors, windows, partitions, cabinet doors, furniture, and glassware, among others.

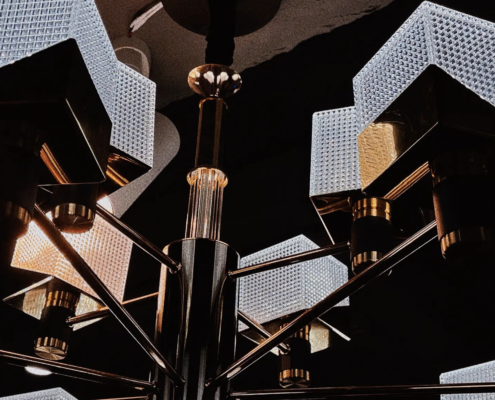

patterned glass provides an aesthetically pleasing visual effect and adds a unique style to interior decoration. Additionally, it offers a certain degree of privacy, as the patterns reduce transparency. This makes it widely used in residential and commercial spaces, creating distinctive decorative effects.

Key Features:

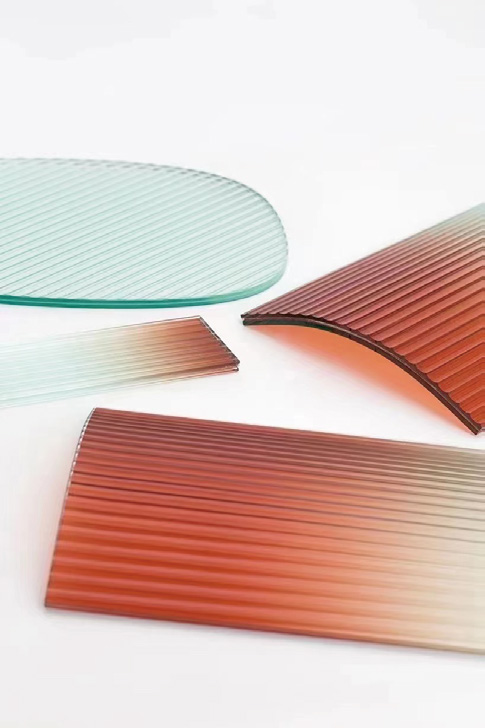

1, Design Flexibility: The manufacturing process of patterned glass allows for a wide range of patterns and designs on the glass surface, making it an ideal choice for creative architects and designers. Various personalized ways can be tailored to match different architectural styles and requirements.

2, Privacy Protection: The textures and patterns of patterned glass provide a degree of privacy without compromising natural light and ventilation. Consequently, it is widely employed in offices, shops, hotels, and medical facilities for partitions, privacy walls, and windows.

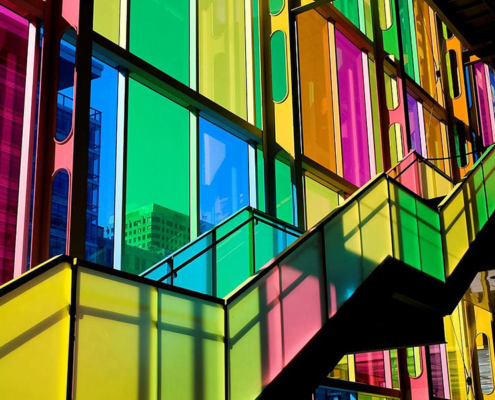

Light Diffusion: patterned glass can diffuse light, creating a soft and uniform indoor lighting effect. This reduces glare and harsh lighting while adding a warm atmosphere to interior spaces.

3, Visual Appeal: The patterns and textures of patterned glass add visual depth and detail to buildings, enhancing their decorative appeal. Its applications range from cabinet doors, shower enclosures, partition walls, and stair railings, to glass windows, offering a myriad of unique design possibilities.

4, Safety: In comparison to regular flat glass, patterned glass offers increased slip resistance on its textured surface, minimizing potential slip hazards.

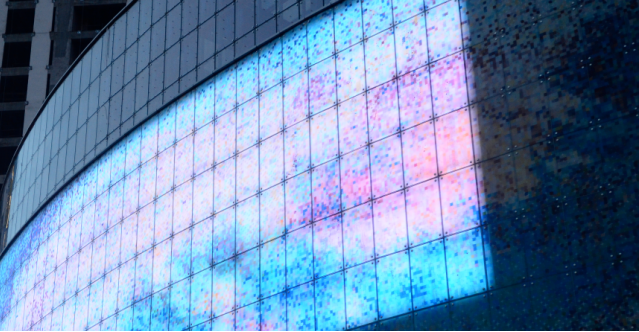

5, Anti-Glare Effect: Applying patterned glass to the exteriors of buildings reduces surface reflections, lessens glare, and enhances the comfort of surrounding environments.

6, Energy Efficiency and Environmental Friendliness: patterned glass can moderately reduce energy transfer between indoor and outdoor spaces, helping to maintain indoor temperatures and lower energy consumption for air conditioning and heating.

7, Versatile Applications: patterned glass finds versatile applications in various aspects of building design, including exterior and interior walls, windows, doors, partitions, and cabinet doors. It can also be combined with other materials such as wood, metal, and ceramics to achieve even more design possibilities.

In conclusion, as a material in the interior and exterior decoration industry, patterned glass offers visually appealing decorative effects and boasts practicality and functionality. Its significance in architectural design and decoration continues to grow, and with ongoing technological advancements, we can look forward to more innovative designs and applications.