Glass Products For The Construction sector, Glass strongly influences modern architectural design. The creative use of large windows, glass doors, roof lights, and atria, among many other applications, makes buildings and houses bright, airy, inviting and energy efficient.

Uses & applications

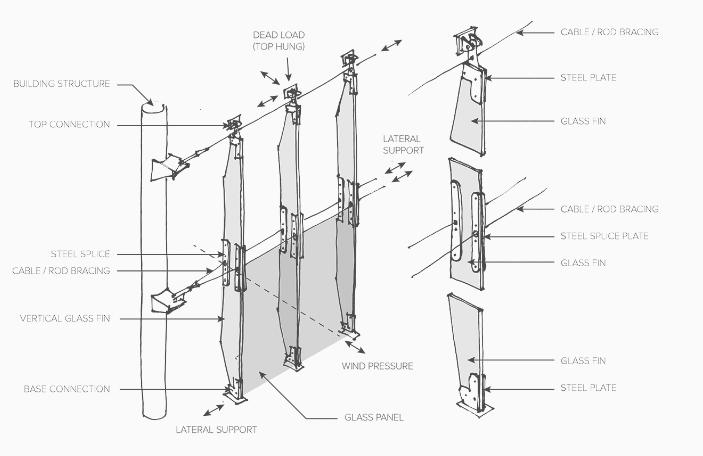

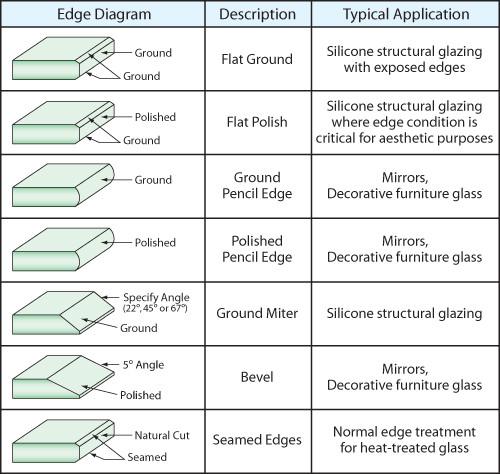

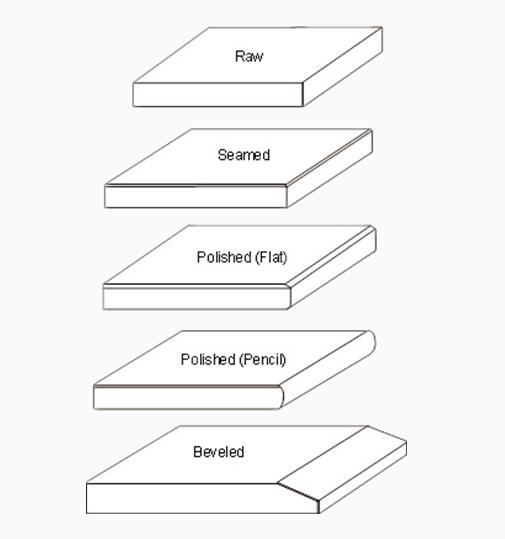

The main uses of glass in buildings and houses are, of course, the most obvious and visible ones: facades and windows. Today’s glass products for commercial and residential buildings represent highly developed technologies, nothing like the simple window panes of the past. Light, comfort, well-being, style, safety and security, and sustainability are among the benefits of today’s high-performing windows and glass building facades. The ability to control heat, light, and sound transmission to a high degree enables architects to design buildings that have a greatly reduced impact on the environment and dwellings that are quiet, comfortable and safe. Glass also finds application in interior decoration and furniture.

Glass in residential houses

Glass proves to be a very attractive and modern alternative to other building materials, such as brick, polycarbonate, or wood. The more glass is used, the more natural light enters the home. This makes the home even more pleasant and comfortable, and, with today’s high-tech glass options, this can come at no cost to security, safety, or environmental sustainability.

Glass in commercial buildings

Today’s glass technologies allow large commercial buildings to be energy-efficient structures that make the most of natural daylight while protecting the environment and the climate and conserving energy.

If you have any ideas, please feel free to contact us anytime.

+86 0755 86152161 inquiry@hongjiaglass.com