PVB vs EVA Laminated Glass

Laminated Glasses

Laminated glass is a combination of two or more glass sheets with one or more plastic inter layers

(EVA /PVB /SGP)sandwiched by the glass sheets. In case of breakage the interlayer will hold the glass fragments together. It is manufactured through a process of heat and vacuuming.

Laminated glass is used when there is a possibility of human impact or where the glass could fall if shattered. It can be found in windshields, skylights, balconies, bank teller windows, and jewelry counters to name a few applications.

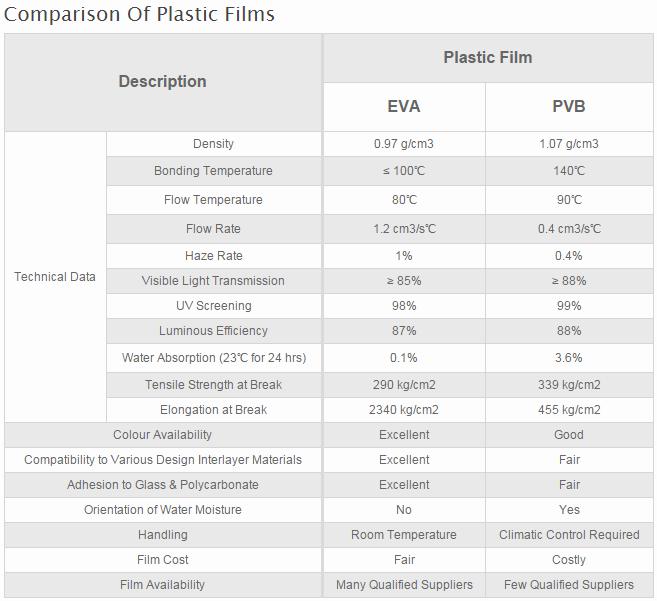

Interlayer Film : SGP / PVB / EVA

Cost: SGP > PVB > EVA

Safety:SGP > PVB > SGP

Color:EVA > PVB > SGP

(also EVA does well connected with many different materials,so it’s a very nice interlayer for decoration glass)

Bulletproof glass is als laminated glass, it is several film and glass laminated.

Normally,it comes with PVB,dear client,if you have enough budget,then think about SGP