With constant development in science and technology, glass curtain walls are finding increasingly more applications and their structures are also experiencing great changes. Fully spider fitting frame-less glass curtain walls, connect glass together in an open space using various types of light/heavy steel structures via various types of spider fitting members to form flexible and unobstructed glass facade. In this way, fully spider fitted glass walls not only maintain the safety of aluminum alloy frame glass curtain wall but also eliminate the disadvantages of the later in singular structure and restrictions from construction structures. As a result they provide unobstructed view as a whole, neat, bright and integrated with such advantages as safety, practicality and artistic taste thus becoming a vogue for modern construction and decorations.

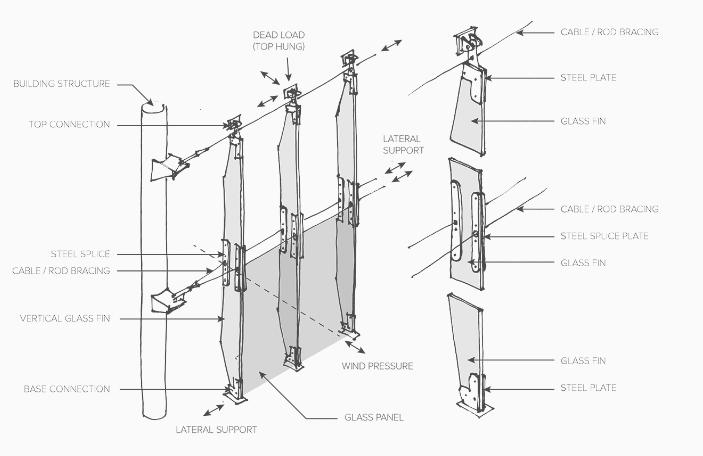

Thermally toughened or tempered glass panels are used as single or insulated glass units. In case of single panels laminated safety glass is preferred due to safety reasons. This system consists of a number of accessories with metal arms. At the end of each arm, a sheet of glass is fixed by the corners with a special screw. The vacuum between these sheets is filled up with isolators to overcome mechanical pressure and weather conditions.

The rectangular glass sheets have 4 or 6 countersunk drilled holes into which countersunk stainless steel bolts acting as point-fixings. The space between the glass panes are filled with weather seal. The support elements that hold the fitting can be space frame, glass fin, tension cables or steel circular columns to provide the aesthetic effect as desired by the customer.