Overview

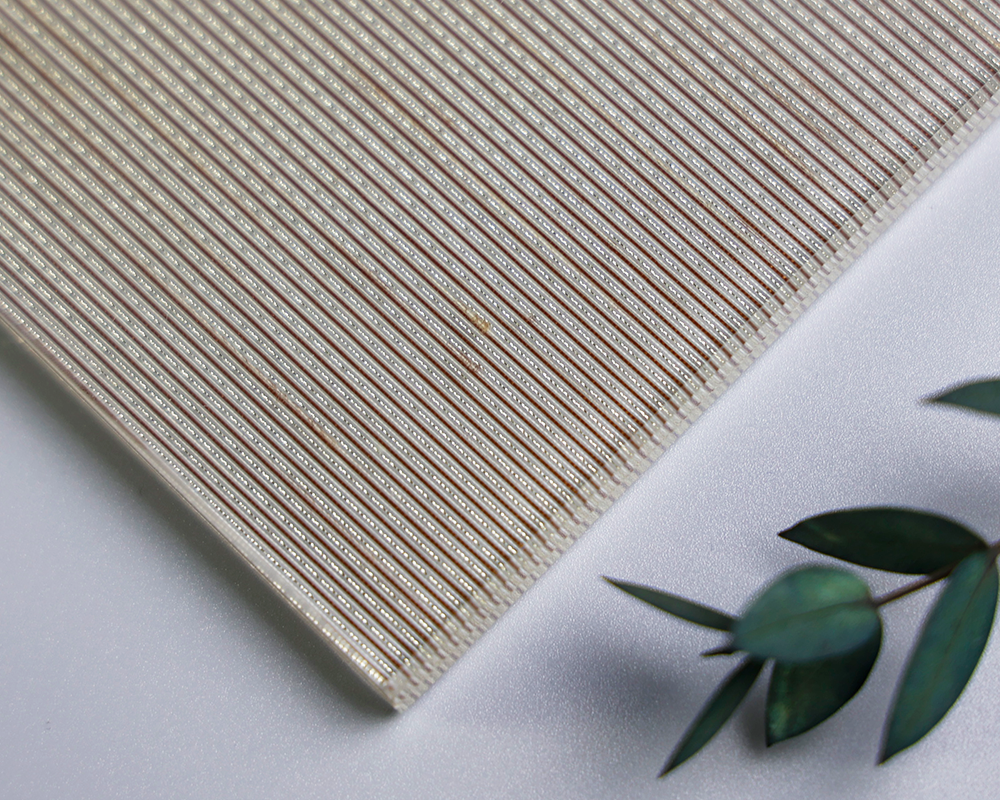

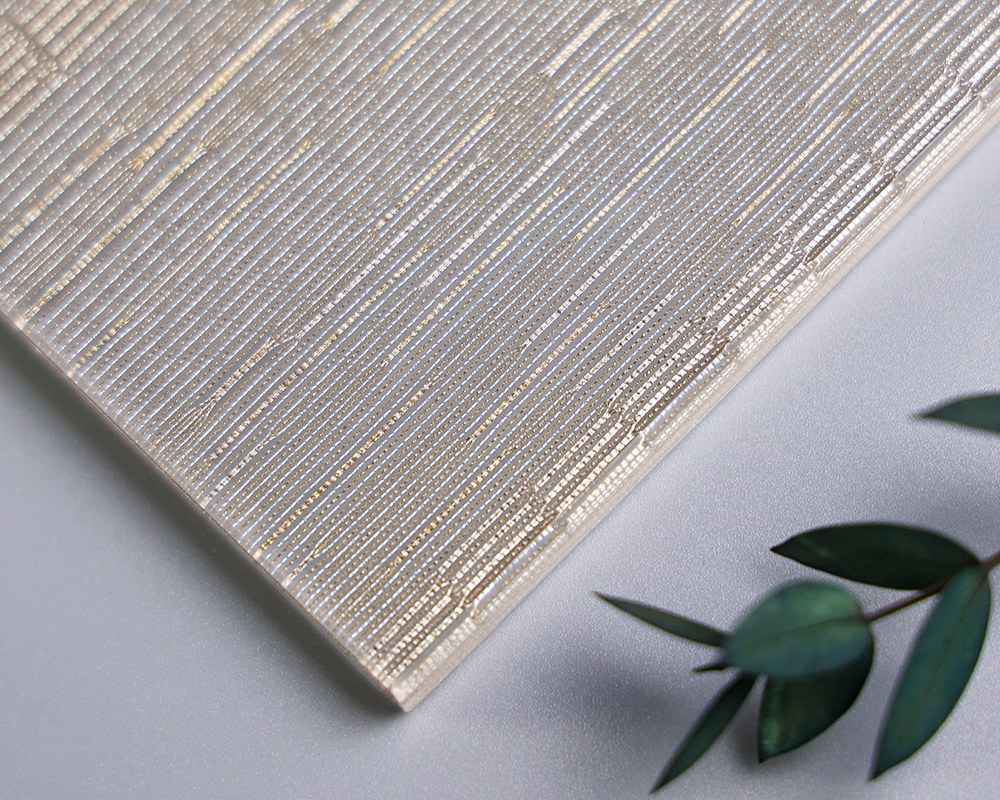

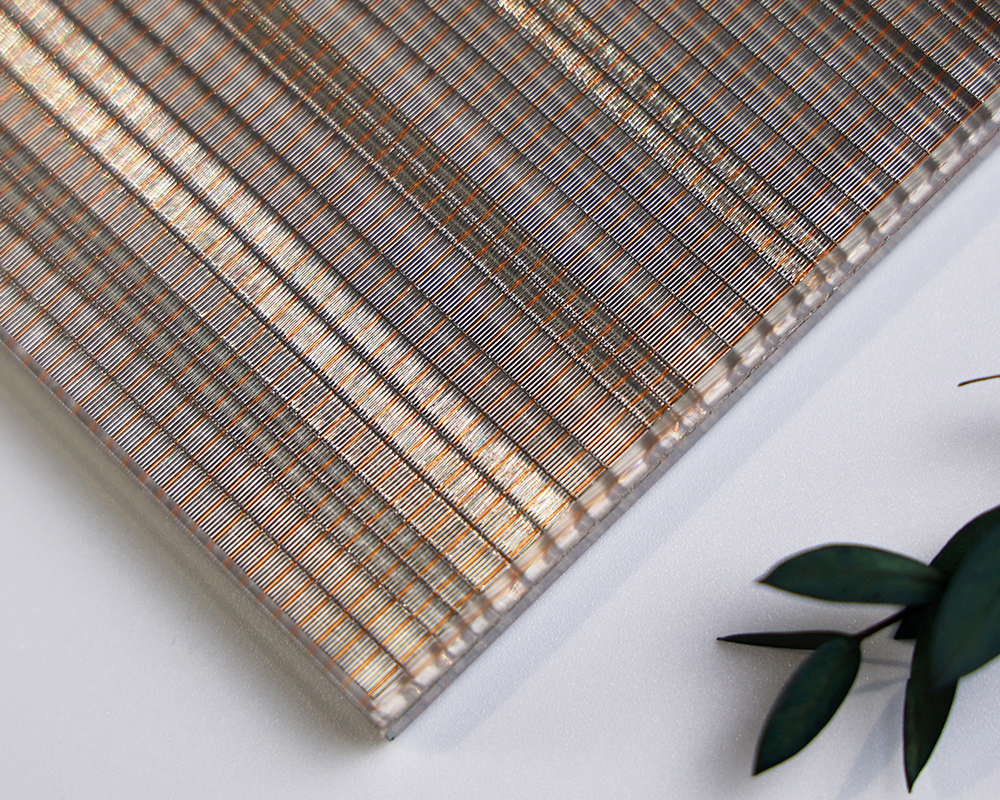

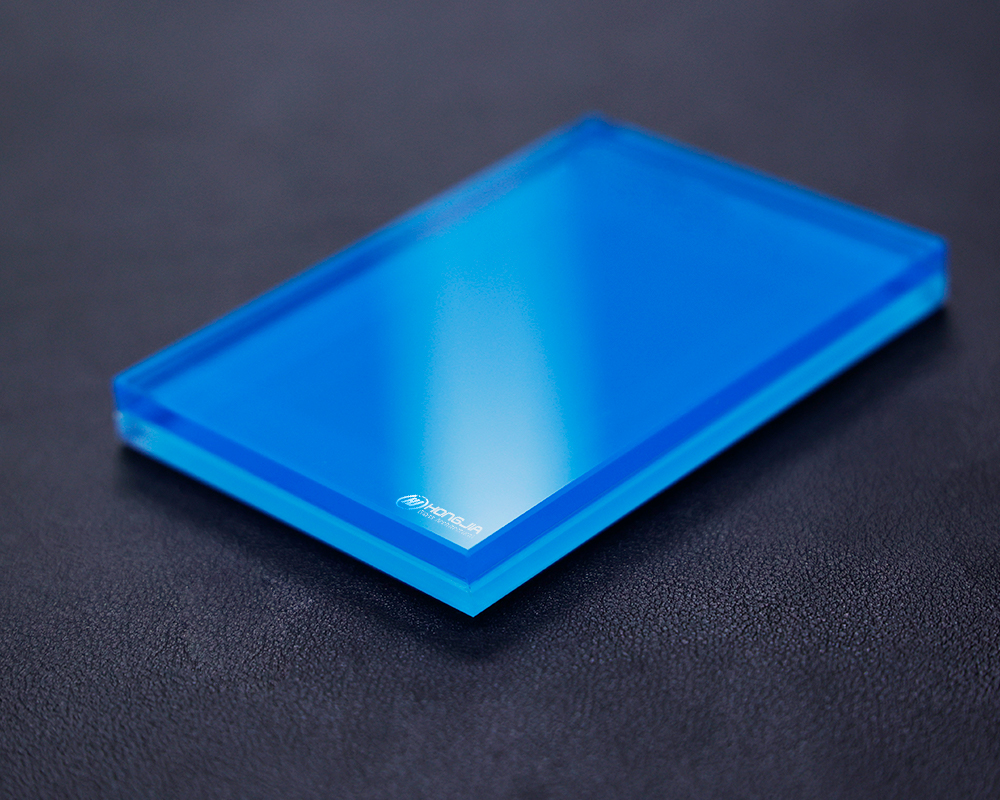

Fabric Laminated Glass

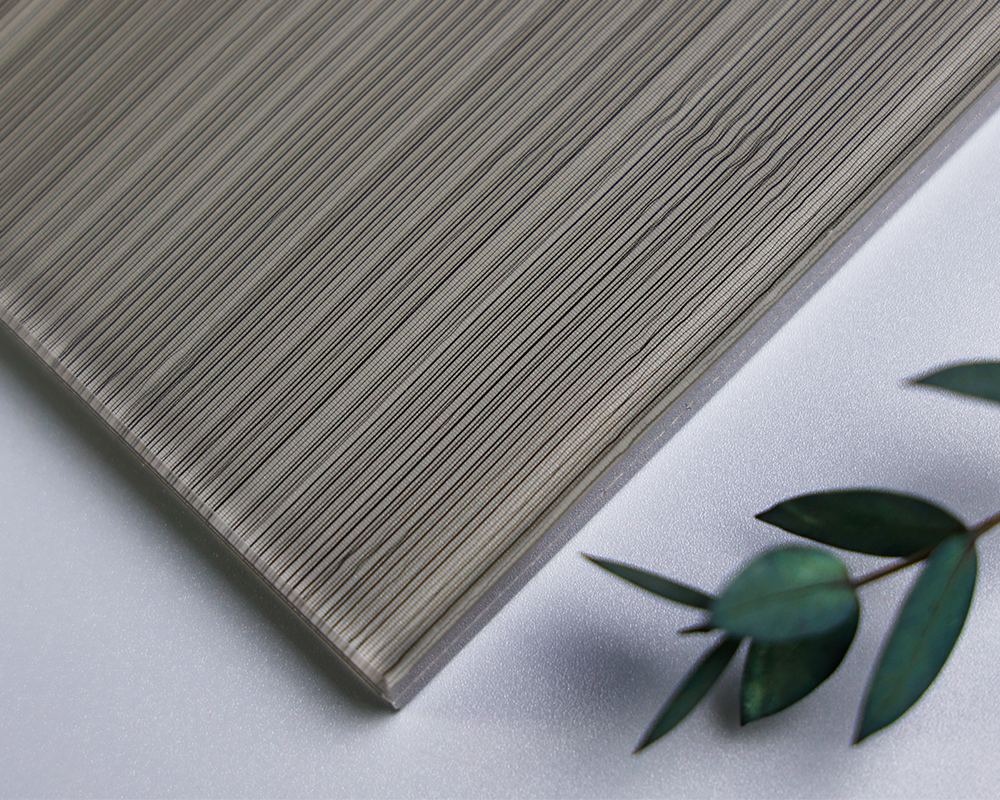

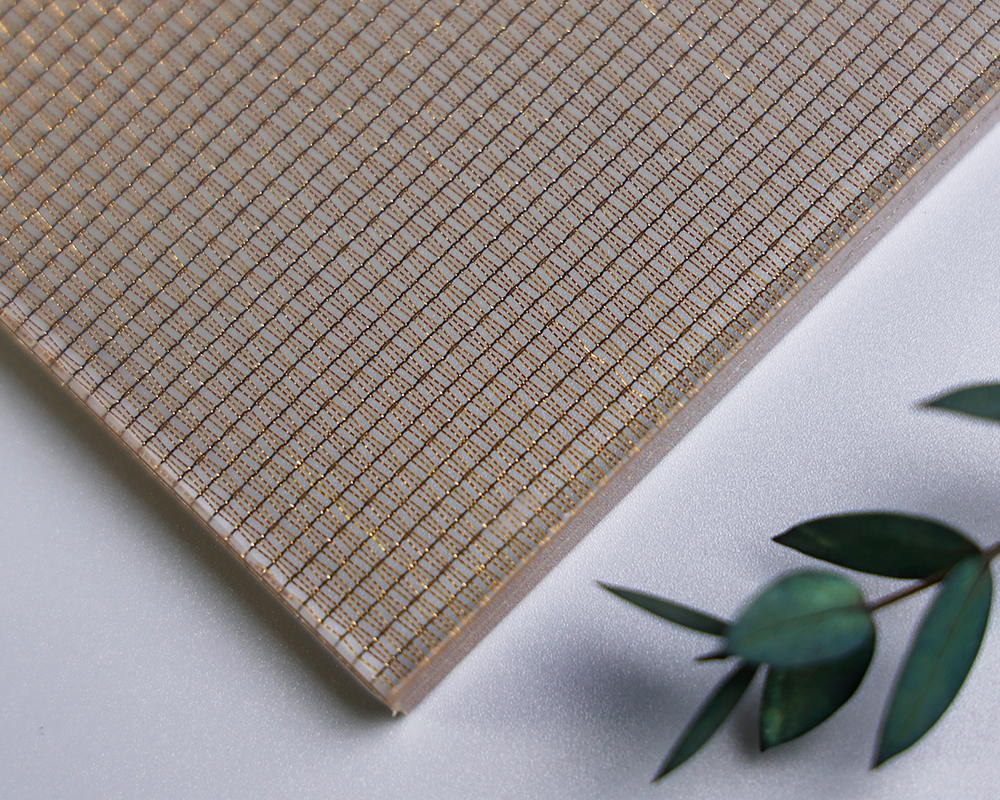

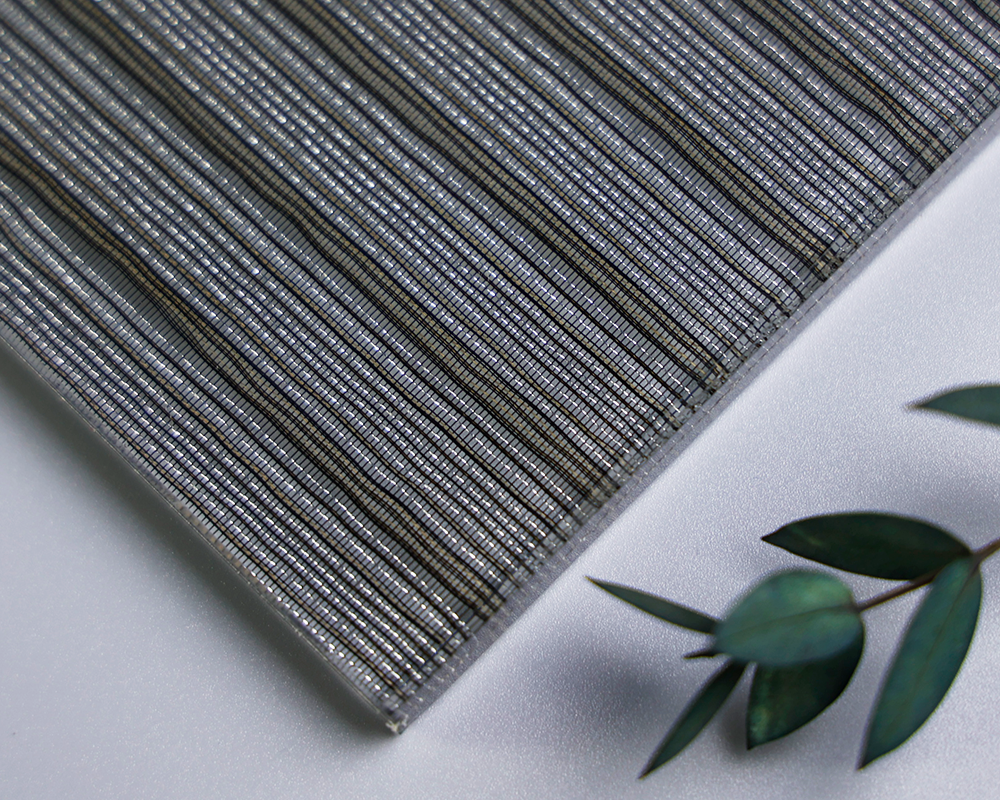

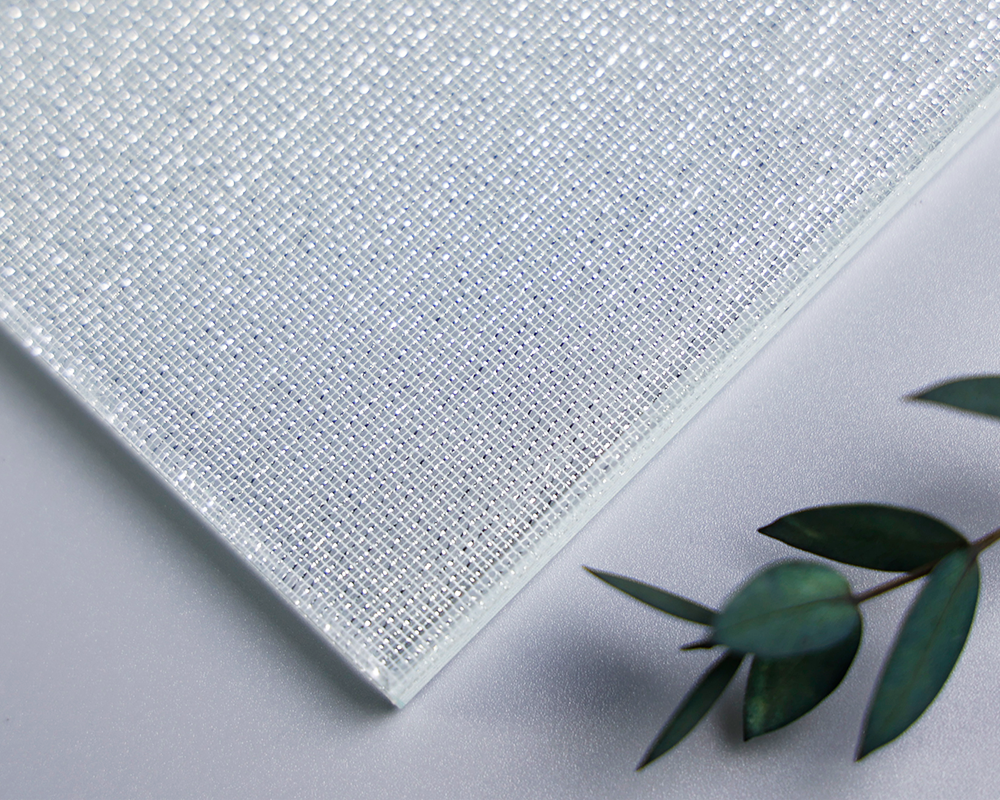

Fabric laminated glass is a type of safety glass that is made by sandwiching a layer of fabric between two or more layers of glass. The fabric layer is typically made of materials such as polyester or nylon and is placed between the glass layers during the lamination process. The result is a glass panel that is stronger and more resilient than ordinary glass, with increased resistance to impact, shattering, and penetration.

Fabric laminated glass is often used in architectural applications, such as for skylights, partitions, atriums, and façades. The use of fabric interlayers allows for a greater degree of customization in terms of color and texture, making it a popular choice for design-conscious applications.

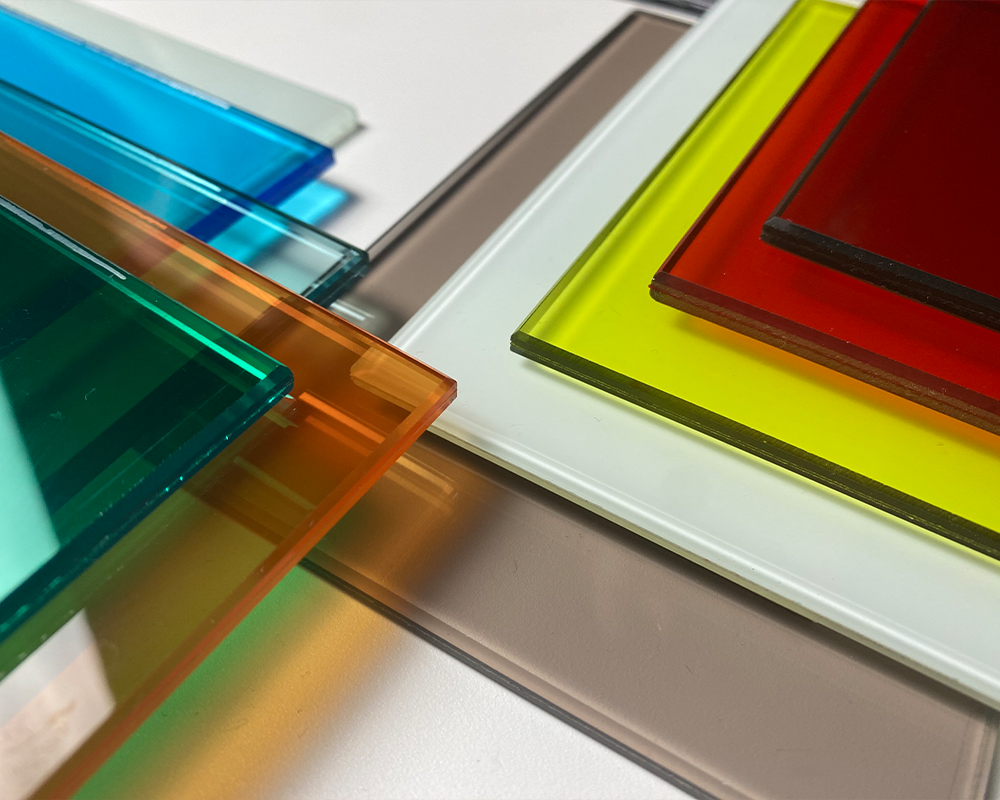

The intermediate layer material of fabric glass can be matched with different combinations of glass, such as mirrors, colored glass, and textured glass, to create unique effects. When paired with indoor lighting and surrounding design, it can add a highlight to your overall design.

Overall, fabric laminated glass is a versatile and effective solution for a range of glass applications.

Glass Max size: 2440mm*3600mm (According to the size of the fabric)

Glass Min size: 100mm*100mm

Min curved radius: depend on the client’s requirement

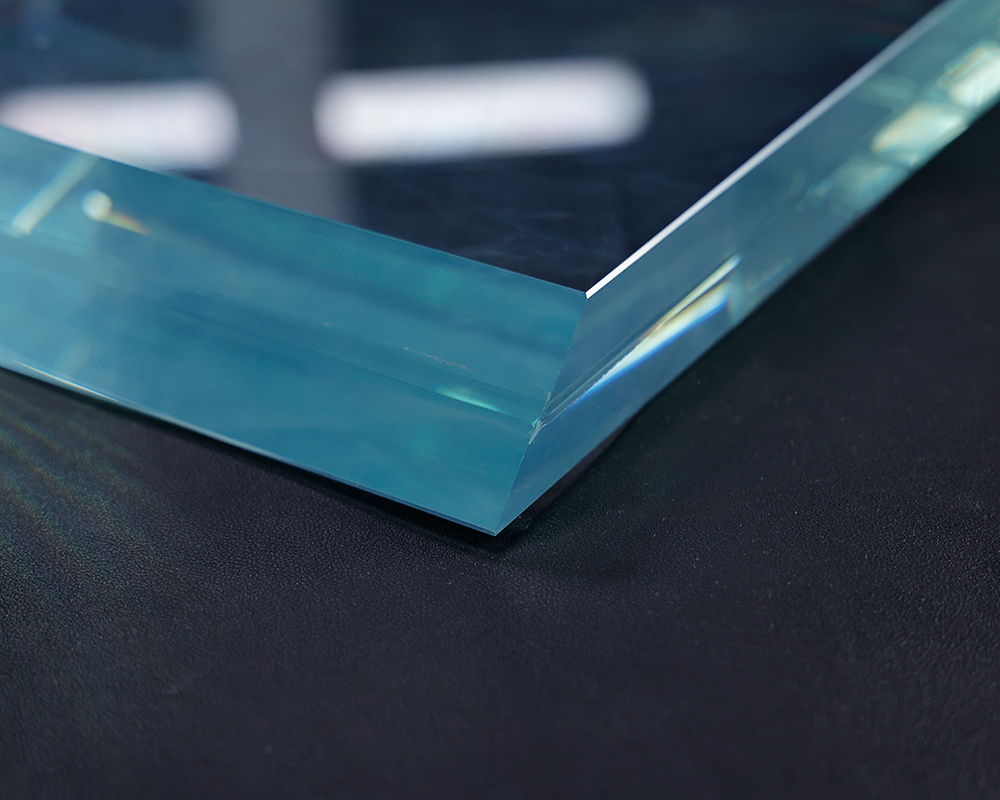

Glass Thickness(mm): 3+3, 5+5, 6+6, 6+8, 8+10, 10+10, 10+12, 12+12, 15+15, 19+19 or triple glazing or multilayer

PVB or EVA Thickness: 0.38mm-3.04mm

Glass color: clear, ultra clear(low iron, crystal clear, star fire), F green, Ford blue, gray, Light Bronze, Deep Bronze, etc.

Packing: Customize fumigation-free sealed wooden boxes according to your quantity and size, and take specific inner packaging protection measures to ensure safety during various transportation

Application

Interior Application: glass partition, shower glass, table top, windows, glass stairs, handrail, bathroom, etc.

Related Product